Low Noise Level Skim Milk Cream Separator Machine

Product Application

The DHNZ series separator features ring valve type automatic slag discharge controlled by computer program and industrial control computer. It performs regular, quantitative slag discharge according to your settings without stopping the feeding process.

Main Features

- High rotating speed for efficient separation

- Exceptional operating stability

- Completely sealed inlet and outlet system

- Low noise operation

- Optimal separation efficiency

Technical Specifications

| Model |

Treatment Capacity (L/H) |

Inlet Pressure (Mpa) |

Outlet Pressure (Mpa) |

Motor Power (Kw) |

Weight (Kg) |

Dimensions (mm) |

| DHNZ360 |

1000-3000 |

0.05 |

0.1-0.35 |

7.5 |

1200 |

1530×1150×1500 |

| DHNZ470 |

3000-6000 |

0.05 |

0.1-0.4 |

15 |

1600 |

1800×1200×1750 |

| DHNZ550 |

5000-10000 |

0.05 |

0.1-0.4 |

22 |

2300 |

1950×1550×1960 |

| DHNZ616 |

10000-20000 |

0.1 |

0.3 |

37 |

3000 |

2185×1728×2082 |

Machine Components

Name: Disc

Brand: Juneng

Origin: China

Each part of the drum is numbered before shipping and should not be interchanged. The disk sets are assembled in sequence on the distributor, with disks and drum cover held on the drum body by disk glands.

Name: Drum

Brand: Juneng

Origin: China

The drum is the high-speed rotating component that performs material separation, serving as the heart of the separator.

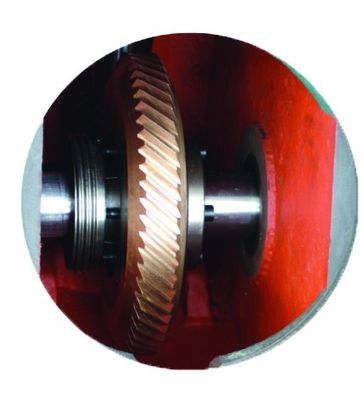

Name: Shaft

Brand: Juneng

Origin: China

The vertical shaft transmits power and is equipped with speed step-up gear (small spiral gear) and high-speed rotating parts. The cross shaft transmits motor power to the vertical shaft and main drum components.

Name: Equipment Base

Brand: Juneng

Origin: China

The underframe supports the entire separator and connects to the base. All four supporting feet feature damping rubber pads that effectively isolate vibration between the separator and building.

Quality Assurance & Testing

Our separators undergo rigorous testing and inspection procedures:

- Material Test Report

- Magnetic Particle Examination

- Nondestructive Examination

- Liquid Penetrant Examination

- Dynamic Balancing Test

- Radiographic Examination

Packaging & Delivery

| Packaging Type |

Details |

| Size |

Varies by model |

| Weight |

1000kg-3000kg |

| Packaging Details |

Standard wooden box packaging (Size: L*W*H). European exports include fumigated wooden boxes. Alternative packaging available for tight containers or special requests. |

| Transport |

Domestic: Road transport | Overseas: Sea or air freight |

Customer Support Services

Pre-Sales Service

- Inquiry and consulting support

- Sample testing assistance

- Factory visit arrangements

After-Sales Service

- Machine installation training

- Operation training

- Overseas engineer support

Our professional after-sales service team provides complete installation guidance, debugging assistance, and operator training until full competency is achieved. We guarantee a 2-hour response time for operational issues and on-site engineer support until complete resolution.

Manufacturer Profile

Juneng Group is a leading Chinese manufacturer specializing in industrial filtration and separation equipment. With over 30 years of experience, we maintain approximately 90% domestic market share in oils & fats, chemical, pharmaceutical, beverage, and petrochemical industries.

Our production facilities span 280,000 square meters across Nanjing and Yixing, staffed by 1100+ employees and equipped with 2000+ advanced production units and testing instruments.

Why Choose Juneng

- Internationally certified production chain

- Manufacturer-direct pricing

- Comprehensive technical support

- Exports to 20+ countries with positive feedback

- Customized project feasibility reports

Frequently Asked Questions

How can we visit your factory?

International visitors: Fly to Shanghai airport (we provide airport pickup). Domestic visitors: Travel to Wuxi station (we provide railway station pickup).

How do you ensure product quality?

As a state-owned enterprise with 30+ years experience, we maintain strict quality control with licensed operators, precision machining, international brand components, and comprehensive testing throughout production.

What payment methods do you accept?

We primarily accept T/T and L/C at sight, along with most standard payment methods.

What is your warranty period?

We provide a 12-month warranty after commissioning.

How can I trust your company as a new customer?

We've been a Golden Supplier on Alibaba for 10+ years with CE, ISO9001, and Alibaba onsite check certifications. Our Trade Assurance Limit exceeds US$42,000.

What are your delivery terms and timelines?

Standard delivery is 20 days (30 days for customized machines), depending on order quantity.

Do you offer discounts?

We strive to provide competitive pricing along with excellent service.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!